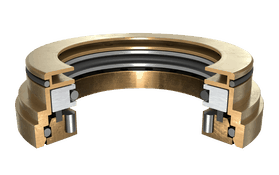

Isomag Magnetic Oil Seals

Features

IsoMag magnetic bearing isolator meet ANSI and API 610 equipment standards. Magnetic oil seals are used in thousands of centrifugal machinery applications. Standard magnetic bearing protectors are available to fit shaft diameters from 3/4″ to 13″.

ROTATING EQUIPMENT APPLICATIONS

- Pumps

- Gearboxes

- Electric Motors

- Steam Turbines

- All Types of Centrifugal Machines

Isomag labyrinth bearings seals work well in all lubrication systems and shaft orientations

- Oil Splash

- Oil Flooded

- Oil Mist

- Grease

- Vertical Up/Vertical Down

MARKETS SERVED

- Pulp and Paper

- Petrochemical

- Oil Refining

- Upstream and Downstream Oil and Gas

- Offshore

- Mining

- Manufacturing

- Food Processing

- Pharmaceuticals

We also perform custom work for OEM’s. In addition, engineered application specific designs are available.

100% POSITIVE SEAL

IsoMag bearing isolators offer all metallic primary construction and are both ANSI, API 610 approved. IsoMag magnetic oil seals outperform both lip and labyrinth seals and offer a range of benefits.

- 100% positive seal bearing protection with or without shaft rotation

- Zero shaft wear

- Bi-directional seal

- Nickel-plated neodymium magnets resist corrosion

- All materials rated to 400°F

- No exposed moving parts

- Self-aligning faces

- Increases equipment MTBF

- Prevents lubrication loss and eliminates contamination (solids, liquids and steam)

- Reduces heat generation and maximizes seal life

- Isolates magnets from lubricant

- Handles low AND high speed applications